Clutch Ring Geometry Validation System

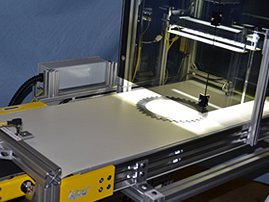

Decision Technology is pleased to announce our newest validation tool to service the transmission/clutch core ring industry. There are 2 versions of the system: area scan camera and line scan camera based. This paper covers the operation with area scan cameras which provides higher geometry resolution, and line scan cameras which is better suited for surface and liner inspection with reduced geometry resolution. This system is based on a belt drive silhouette processing design and Decision Technology’s 10 years plus experience in the development of clutch ring (steel and lined) processing software and hardware. This new design is meant for hi-resolution geometry and LOM (lack of material) processing. Typical standard features include:

- Processing rates as high as 72 PPM (typical for geometry only) as rates will drop based on selected processing features.

- Various Camera/Geometry resolutions (see camera resolution below)

- Compatible with just about all tooth configurations including scalloped teeth and mixed teeth combinations.

- Embedded eject (pushes failed parts off the belt), drop-gate eject also available

- OD part range: 4.7 to 10.8 inches (smaller and larger part ranges are available)

- Build on a Windows 7e industrial processor

Standard geometric features include:

- Diameters (ID, OD, Minor OD/ID, slot)

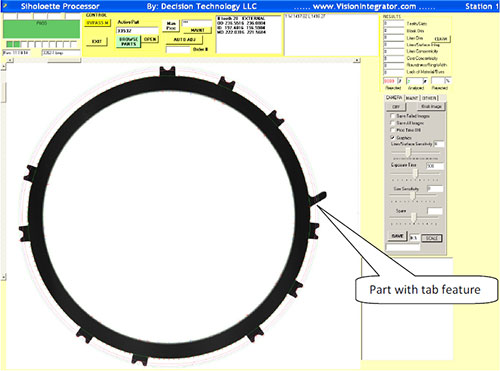

- Number of teeth including: full width, half width, scalloped, short height and tabs

- Blank concentricity, OD to ID

- Ring width (tooth crown to opposite diameter)

- Roundness, several methods available and is based on part presentation

- Basic slot length

- Identifies correct part number (based on geometry)

Optional features include:

- Higher speed processor, required for LOM processing

- LOM (Lack of material) processing (see below for more details).

Camera Resolutions include:

- Low (1600x1200 pixel camera resolution) .009-inch resolution - This arrangement is recommended for reasonable dimensional and LOM checking and for wrong part sorting.

- Medium (2448x2050 pixel camera resolution) .0053-inch resolution – This arrangement is recommended for good dimensional and tight LOM checking.

- High (3388x2712 pixel camera resolution) .004-inch resolution – This arrangement is recommended for hi resolution measurement and tight LOM checking

Decision Technology developed the processing software behind these systems; as such special requests are something we can usually accommodate.

The statistical processing applied to most of the measurement algorithms significantly improves the resolution of most measurement results, as verified in the following test results. Recent repeatability studies yielded a peak deviation of less than 1/2 pixel and a standard deviation less than 1/4 pixel. It should be pointed out that part edge quality plays a major role in such measurements.

A repeatability test was run by an outside party on a good part using the high resolution camera. The following geometric results were from 2 parts each run through 10 times (in mm.):

| OD | ID | Minor | Roundness | |

|---|---|---|---|---|

| Min: | 222.0330 | 203.5070 | 217.8341 | 0.3602 |

| Max: | 222.1118 | 203.5638 | 217.9303 | 0.4038 |

| Average: | 222.0702 | 203.5347 | 217.8827 | 0.3868 |

| Peak: | 0.0788 | 0.0568 | 0.0962 | 0.0436 |

| Stdev: | 0.0255 | 0.0189 | 0.0280 | 0.0153 |

| OD | ID | Minor | Roundness | |

|---|---|---|---|---|

| Min: | 222.0492 | 203.5327 | 217.8134 | 0.3454 |

| Max: | 222.1119 | 203.5957 | 217.9281 | 0.4060 |

| Average: | 222.0748 | 203.5531 | 217.8694 | 0.3801 |

| Peak: | 0.0627 | 0.0630 | 0.1147 | 0.0606 |

| Stdev: | 0.0237 | 0.0203 | 0.0354 | 0.0222 |

We consider these results somewhat typical; however there is no guarantee that these results can always be achieved. There are many factors involved to achieve such excellent results. The following is a ring with a tab feature and scalloped teeth.

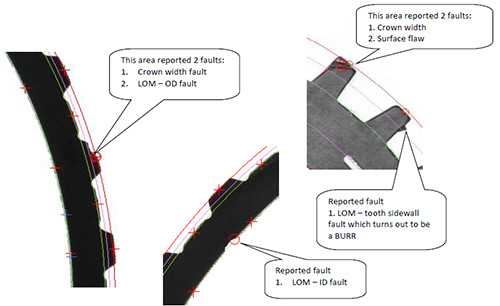

Lack of Material (LOM)

Lack of material of the core is offered as an option and typically requires the medium or high resolution camera option and the hi-speed processor option; it is very processor intensive. It features:

- LOM along the crown of the teeth

- Crown width

- LOM along the various ring diameters

- LOM along the sides of the larger, straight sided teeth

These features typically have a minimum detection resolution of 3 camera pixels (~.015″/.38mm for medium-resolution camera). Edge roundness can increase this value and is therefore recommended measuring in the roll edge facing down position. Not all LOM processing is available on all product features, for example small rounded teeth. Typically this processing will pick up burrs as well, however under certain circumstances dirt on the belt can be interpreted as a burr.

Typical material variations on the order of 3-4 camera pixels can be detected.

Typical examples of actual detected LOM & BURR faults

Decision Technology maintains a medium resolution version of this system in house. It is used to develop and refine processing algorithms, and for customer demonstration on their parts. This provides for purchasing confidence. Contact us for availability.

All results are stored in a CSV format log file which exports easily into Excel. Both the hardware and software can be scaled (size and camera resolution) to accommodate families of larger or smaller parts. These systems have been designed and built to significantly reduce the probability of a bad part going out the door.

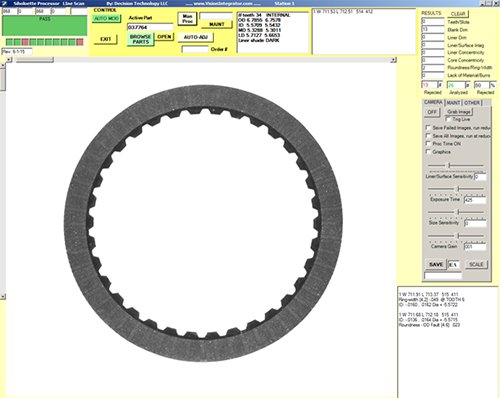

Line Scan Camera Version

The line scan camera version can perform geometry and LOM processing, but to a lesser degree of repeatability. However it can perform surface inspection on steel parts and liner inspection on friction lined parts. Two systems can be run in tandem to perform processing on both sides of the ring. Due to the processing techniques, line scan is not recommended for critical roundness measurements.

The following results are provided from a 2-k line scan camera system. Units are metric.

| OD | ID | Minor | Roundness | Core Concentricity | |

|---|---|---|---|---|---|

|

246.5417 |

180.3288 |

225.0173 |

0.1611 |

0.017382 |

|

|

246.5601 |

180.4488 |

225.2001 |

0.1992 |

0.067716 |

|

|

246.6447 |

180.3803 |

225.0741 |

0.1279 |

0.059714 |

|

|

246.614 |

180.442 |

225.0956 |

0.0924 |

0.076375 |

|

|

246.5378 |

180.4672 |

225.1182 |

0.132 |

0.026755 |

|

|

246.5845 |

180.5727 |

225.1451 |

0.1619 |

0.077526 |

|

|

246.5623 |

180.5376 |

225.1709 |

0.0882 |

0.051570 |

|

|

246.5525 |

180.5079 |

225.1843 |

0.3241 |

0.069527 |

|

|

246.5487 |

180.5141 |

225.0895 |

0.114 |

0.059202 |

|

|

246.539 |

180.3628 |

225.0348 |

0.0657 |

0.061131 |

|

|

246.5589 |

180.5405 |

225.1477 |

0.129 |

0.066375 |

|

|

246.4983 |

180.3042 |

224.9454 |

0.1275 |

0.107711 |

|

|

246.6895 |

180.4589 |

225.1033 |

0.0751 |

0.099602 |

|

|

246.6034 |

180.3048 |

225.0087 |

0.1549 |

0.083944 |

|

|

246.6178 |

180.3883 |

225.0524 |

0.1238 |

0.052276 |

|

|

246.6038 |

180.5283 |

225.117 |

0.1755 |

0.113465 |

|

|

246.6206 |

180.4338 |

225.0859 |

0.1461 |

0.039264 |

|

|

246.4623 |

180.4232 |

225.0242 |

0.1851 |

0.081216 |

|

|

246.5938 |

180.3242 |

225.0323 |

0.0394 |

0.098627 |

|

|

246.5798 |

180.4111 |

225.0802 |

0.1604 |

0.067559 |

|

|

246.7093 |

180.425 |

225.1294 |

0.1213 |

0.038789 |

|

|

246.5754 |

180.4546 |

225.0848 |

0.0871 |

0.089195 |

|

|

246.596 |

180.4639 |

225.1501 |

0.3501 |

0.057935 |

|

|

246.6835 |

180.6307 |

225.2057 |

0.3501 |

0.076954 |

|

|

246.6091 |

180.3786 |

225.0616 |

0.0242 |

0.051081 |

|

|

Min: |

246.4623 |

180.3042 |

224.9454 |

0.0242 |

0.0174 |

|

Max: |

246.7093 |

180.6307 |

225.2057 |

0.3501 |

0.1135 |

|

Peak: |

0.2470 |

0.3265 |

0.2603 |

0.3259 |

0.0961 |

|

Average: |

246.5875 |

180.4413 |

225.0943 |

0.1486 |

0.0676 |

|

Stdev: |

0.0567 |

0.0850 |

0.0645 |

0.0845 |

0.0239 |

In this instance a 1K camera was used for processing liner (ECC & defects). Units are in inches

Typical friction lined part 15 run repeatability test. Dimensions are in inches. This was run with a 1k line scan camera: ~ .0095 inch resolution, typically a 2k would be used.

|

OD |

ID |

Minor |

Liner DIA |

Roundness |

Core Concentricity |

Liner ECC |

|

|---|---|---|---|---|---|---|---|

|

6.774969 |

5.560991 |

5.318368 |

5.695713 |

0.0027 |

0.007967124 |

0.005484193 |

|

|

6.777041 |

5.563953 |

5.319204 |

5.700299 |

0.0046 |

0.003994382 |

0.004376301 |

|

|

6.774913 |

5.561046 |

5.321213 |

5.696205 |

0.0002 |

0.007263673 |

0.004815721 |

|

|

6.781099 |

5.570412 |

5.326 |

5.704893 |

0.0156 |

0.005752637 |

0.004215539 |

|

|

6.780466 |

5.565 |

5.321559 |

5.697019 |

0.0051 |

0.007011775 |

0.00324462 |

|

|

6.77521 |

5.56123 |

5.320133 |

5.693896 |

0.0053 |

0.005926647 |

0.00553083 |

|

|

6.774148 |

5.562295 |

5.323251 |

5.696359 |

0.0006 |

0.006424165 |

0.005161362 |

|

|

6.773772 |

5.559915 |

5.318566 |

5.69518 |

0.0034 |

0.009573543 |

0.005218274 |

|

|

6.76865 |

5.561517 |

5.321579 |

5.696764 |

0.0026 |

0.006782458 |

0.00450815 |

|

|

6.770044 |

5.558635 |

5.317843 |

5.692656 |

0.0002 |

0.008318362 |

0.004430336 |

|

|

6.780658 |

5.565038 |

5.324408 |

5.699709 |

0.009 |

0.007703685 |

0.00468567 |

|

|

6.774911 |

5.562772 |

5.32162 |

5.693588 |

0.0005 |

0.008014205 |

0.002204567 |

|

|

6.776783 |

5.564658 |

5.323737 |

5.702803 |

0.0062 |

0.003412259 |

0.005783193 |

|

|

6.775638 |

5.559398 |

5.31918 |

5.69205 |

0.0029 |

0.00661371 |

0.004636863 |

|

|

|

6.771924 |

5.564151 |

5.318612 |

5.695044 |

0.0018 |

0.00533335 |

0.006537 |

|

Average: |

6.7753 |

5.5627 |

5.3210 |

5.6968 |

0.0040 |

0.0067 |

0.0047 |

|

Peak: |

0.0124 |

0.0118 |

0.0082 |

0.0128 |

0.0154 |

0.0062 |

0.0043 |

|

Stdev: |

0.0036 |

0.0030 |

0.0025 |

0.0037 |

0.0041 |

0.0016 |

0.0010 |