Home > Case Studies >

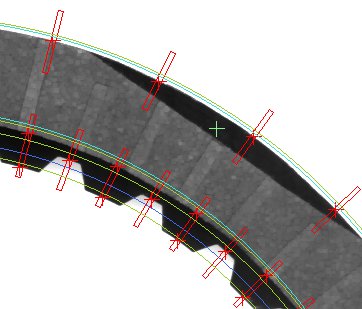

Friction Liner Inspection

This is an early generation system used to inspect friction lined clutch rings at a rate close to 1.8 PPS. In addition to the inspection of ring geometry it looked for liner defects including:

- Liner concentricity to the ring

- Scrapes & gouges

- Cracks, missing material

- Under/Over hang

This is a dual system that checks both sides. Since this generation machine, the friction material processing software has been incorporated into our latest generation belt drive system. As such a single processing application can inspect: geometry, lack of material (ring), ring surface, and friction liner.