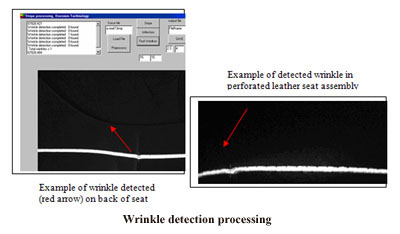

A Machine Vision Approach to Detecting Wrinkles in Leather Car Seats

Unwanted wrinkles are an undesirable blemish associated with the manufacturing process of automotive seats. Decision Technology has developed a machine vision method for inspection and detection of such blemishes.

The developed approach uses a structured light (metrology) technique that can detect wrinkles in non linear (uniform) surfaces typically associated with the complex contours found in automotive seat assemblies. The approach checks along a slice of a contoured surface and detects high frequency dimples against a sliding mathematical spline.

This approach uses a structure light technique so it is best used to spot check known problem areas. The structured light approach makes it robust enough to work over the wide range of fabric colors typically associated with automotive seats (white to black and everything in between). Resolution, the smallest detectable wrinkle size, is primarily based on sensor field of view. The sensor can be robot mounted such that a preprogrammed robot path can move the sensor to various regions of the seat assembly for inspection. Of course inspection timing is related to sensor field of view, processing power and robot path motion.