Machine Vision System Inspects Transmission Clutch Facings & Friction Rings at a Rate of “3 Per Second” with 100% Accuracy and No Human Labor or Errors

A Revolutionary System Already Proven in One of the Industry's Leading Plants

When one of the nation's leading clutch facings manufacturers wanted to improve their inspection process, they relied on Decision Technology to develop an innovative system like the industry had never seen before. Specializing in Vision-Based Inspection and Automation Systems, Decision Technology used its experience to succeed where many had tried and failed. Using custom developed software algorithms and a unique hardware configuration, the Decision Technology system performs exceptionally well, achieving both high speeds and unprecedented accuracy (to thousandths of an inch).

Here's some of what the system can inspect / measure...

- Outside diameter within a specified range

- Inside diameter within a specified range

- Number of full teeth and partial teeth and specific tooth patterns

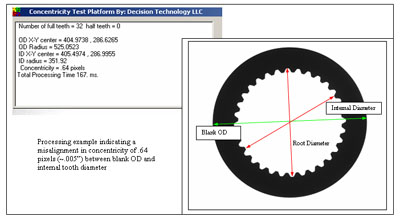

- Concentricity between OD and ID (blank and tooth pattern).

- Ring width at the location of each tooth (OD to tooth crown)

Decision Technology's inspection system is also very versatile, with the ability to inspect clutch facings with a wide range of diameters ranging from 4 - 11 inches (and the system can be modified for larger or smaller components as well). The system can also inspect facings with or without gear teeth (inlay on either the OD, ID, or both).

Manufacturing precision parts and having 100% inspection is more important today than ever. With an integral part like a clutch facing, where a defective part can cause serious problems later, it is critical to find the bad parts as early in the manufacturing process as possible. That's what the Decision Technology system does. At blinding speeds of 180 parts per minute, each facing is completely inspected, with images as high resolution as 4MB, and the bad parts are automatically ejected from the system.

Manual labor, human error, slow inspection processes, etc. are now a thing of the past. To learn more about this system and how Decision Technology can help you improve your quality, increase your production, and decrease your costs, please see below and contact us today!

Details About This System

The heart of the processing is a series of special software algorithms developed by Decision Technology. The first algorithm was developed to determine the number of teeth (full and half-width) along with their corresponding root or crown edge points. The second performs a recursive least-squares-fit to a circle along the perimeter edge points. This determines both X-Y center point and radius for both OD and ID. Such a mathematical approach has the benefit of increased accuracy as more points along the edge are processed.

System accuracy, typically on the order of several thousands on an inch, is based on several key system parameters including: Camera field size (a function of the maximum blank diameter), camera type and resolution, number of edge points used in the circle fit processing, processing time allotment, curve fit filter iterations, calibration, lighting, etc. The above example used a medium resolution camera (768 x 576 pixel image format) focused over a 6-inch field of view (FOV). Line-scan cameras can easily achieve 2K by 2K images and more. Processing speed of 180 PPM have been obtained with 2K line scan cameras, 4 mega-pixel image.

Download Informational Sheet (215K , PDF)