Home > Case Studies >

Non-Contact Measurement and Inspection Tool for Bolt Threads

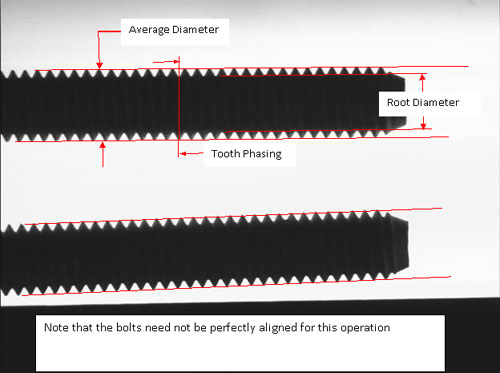

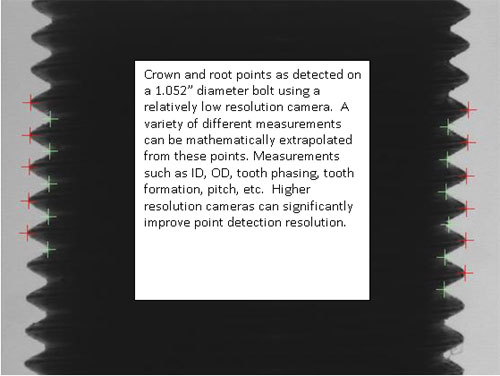

Decision Technology has developed a machine vision based methodology to inspect various characteristics of threaded components. This application can process 2 to 5 components per second based on measurement requirements, camera resolution and processor. In this particular application, two bolts per image are being processed for:

- Average root and crown diameter

- Tooth Phasing

- Tooth count (general thread formation)

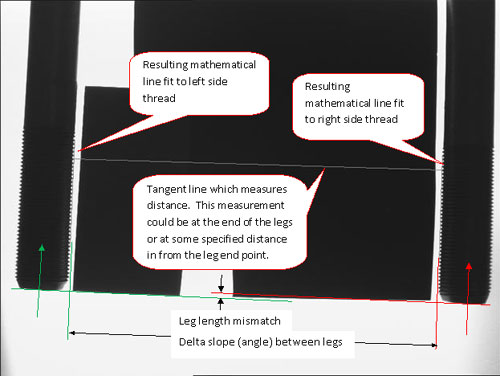

An extended application of the thread algorithm has also been developed to inspect and validate key measurements on U-Bolt. Such measurements include:

- Leg Parallelism

- Leg Length Mismatch

- Spread

Custom systems can be developed to suit specific material handling and part presentation needs.