Flat Part High Speed Inspection System

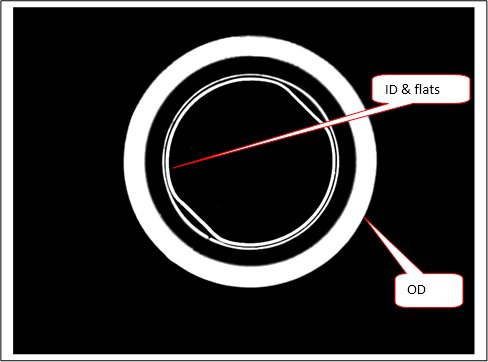

Decision Technology’s hi speed clutch ring inspection system was developed specifically for the inspection (geometry, lack of material, and surface anomalies) of round rings of various diameters. This system has an inherent modular design in that it can host a variety of cameras, both line scan and area scan. Additionally the base platform can be upsized or downsized to handle larger or smaller parts. With this platform, the system can easily be adapted to handle other geometric shapes such as punched/stamped parts. Some additional processing tools may be required, but that’s what we do. Typically our measurements are based on sub-pixel edge detection and processed with statistical processing algorithms to maximize accuracy.

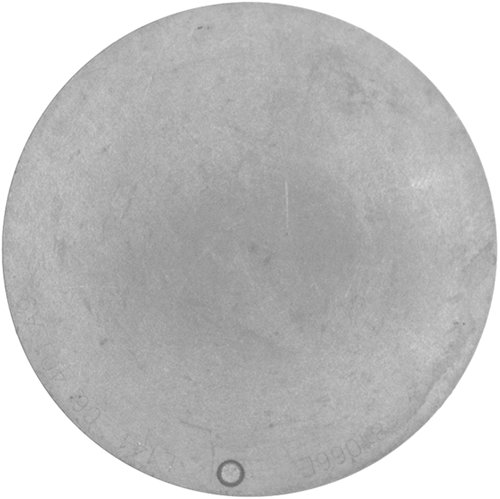

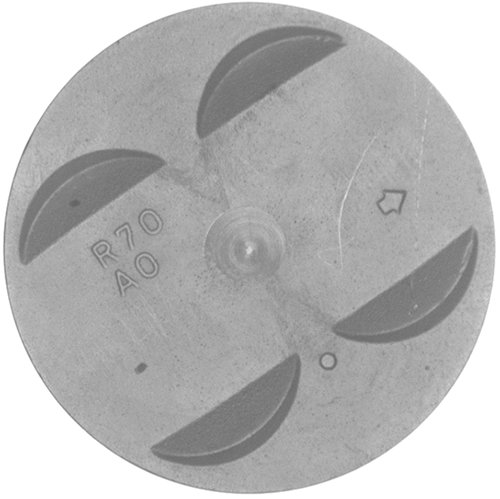

This technology can be applied to parts such as: washers, flat pack battery cells, tops of parts such as pistons (see below), brake pads, etc.

If you have a flat part that needs inspection, let us know your requirements and we work with you to develop a cost effective solution.

Checks for OD, ID, concentricity and unwanted bends in the ring